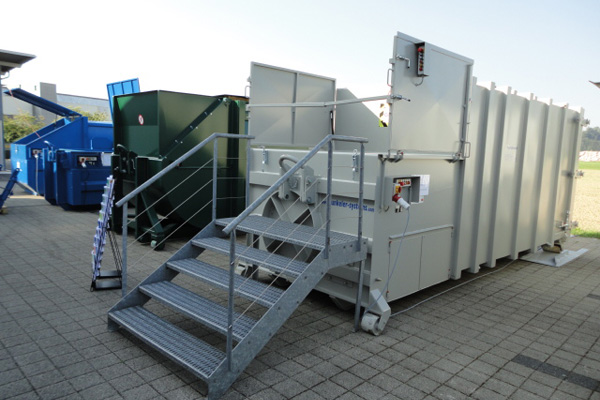

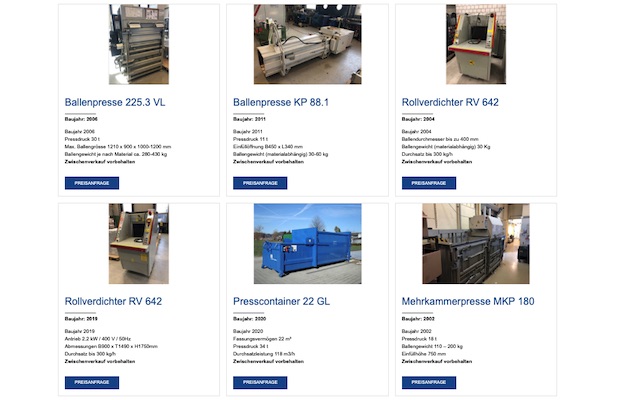

Compaction and disposal of residual waste

Presscontainers from Hunkeler Systeme AG

Residual waste is generated in every commercial and industrial sector. This ranges from packaging material to raw materials from production to direct waste. The disposal of these materials is often problematic and labour-intensive. With the help of a press container, residual waste of various classes is compressed quickly and conveniently. The combination of a compactor and a container provides a system that enables quick disposal. A great advantage of the containers is that they are extremely versatile in use. Thus, there are numerous applications in commerce, trade, industry and other sectors. The containers are designed to be transported by truck. This eliminates the need for internal company transports or space-intensive interim storage. As soon as a container is full, the disposal company of your choice picks up the residual materials. All compactors can be supplied with lifting and tipping devices for emptying collection containers. A variety of lids to cover the feed openings is available, so that the compactors can easily be installed outdoors.