Cardboard presses vertical

Baling presses – an economical disposal solution

Whether you need to dispose of paper, cardboard, or other recyclables, balers make disposal easier. The balers are an uncomplicated and economical solution, as they reduce the volume of the material to be disposed of by 20 times. It does not matter whether it is a large or small amount of waste or production residue. Place the baler where the material is generated. The compact bales are easy to stack and transport. This saves you space and money. In the Hunkeler Systeme range, you will find balers that are perfectly tailored for you.

Hunkeler balers reduce the volume of your waste by up to 95%. This saves you valuable space that bulky packaging materials need on your premises. And with unmixed bales, you generate a secondary raw material that can be reintroduced into the recycling cycle. What’s more, bales above a certain weight have considerable market value, meaning that you may not have to pay for disposal, but you can generate additional revenue.

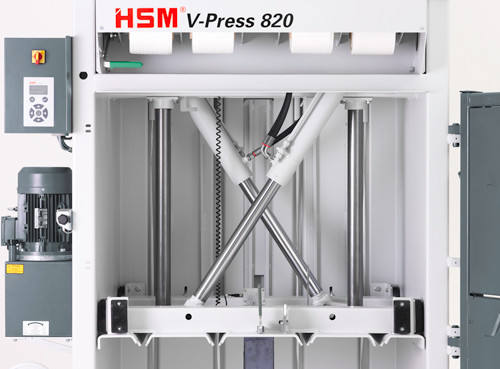

The Hunkeler V-Press in compact advantages

Attractive price-performance ratio

The Hunkeler V-Press series combines the demand for quality with high profitability. Its performance and durability make it an economical disposal solution: The V-Press reduces costs in the mostly underestimated cost center “waste disposal”.

Energy efficient and quiet

With the rapid traverse technology developed at Hunkeler specifically for the V-Press series, power consumption and drive power are significantly reduced while simultaneously increasing throughput. With this technology, the cycle time is reduced by up to 40% compared to conventional drives. Thanks to a special pump technology, the machines are particularly quiet.

User friendly handling

Closing the door starts the pressing process fully automatically. The text display informs the operator in detail about the machine status. If a baler with a sliding door is selected, it opens automatically after the baling process. The bale is ejected at the push of a button and is ergonomically designed. The bale is ejected onto a pallet.

High application flexibility

With the Hunkeler V-Press, you can switch at the touch of a button whether you want to press cardboard or film.

Extremely high process warranty

Thanks to the special TCS (TorsionControlSystem), the inclination of the pressing plate is continuously monitored in all directions. This prevents one-sided loads, optimizes the pressing process and thus ensures a long service life.

The door variants

Double door

- To fill the press, the upper half of the door is swung open to the right

- Self-locking closure technology

- Automatic start after closing the door

Filling flap

- The door flap is folded down to fill the press

- The door flap can be used as a shelf

- Especially suitable for filling with small format material

- Automatic start of the pressing process after closing the door

Sliding door

- To fill the press, the upper half of the door is pushed downwards

- Opens automatically after the pressing process

- Patented door locking technology

- Automatic start after closing the door

The door latches

Knee lever door latch

- Quick and safe opening of the door

- Suitable for machines up to 40 kN pressing force

Handwheel door latch

- Opposed thread for fast opening and closing

- Mounted at ergonomic height

- Opening aid for expansive materials

Hydraulic door lock

- Convenient opening and closing via two-hand operation

- Especially suitable for strongly expanding material

- No manual effort required

The models

HSM V-Press 503 eco

With the entry-level model V-Press 503, you will succeed in disposing of your small cardboard boxes and films economically.

HSM V-Press 504

Easy installation and operation make the V-Press 504 a suitable model for low material volumes.

HSM V-Press 605

The V-Press 605 economically reduces the volume of small cartons or films.

=> Machine in stock, available in approx. 2 weeks

HSM V-Press 610

The V-Press 605 economically reduces the volume of small cardboard boxes or films. With increased pressing pressure for even higher bale weights.

HSM V-Press 818

Thanks to a very low transport height, the V-Press 818 can be easily transported to any place of operation.

=> Machine in stock, available in approx. 2 weeks

HSM V-Press 825

The HSM V-Press 825 is characterized by its very low transport height. With increased baling pressure for even higher bale weights.

HSM V-Press 860

With a pressing force of 594 kN and low-noise, energy-saving technology, the V-Press 860 is the economical solution for your disposal tasks.

=> Machine in stock, available in approx. 2 weeks

HSM V-Press 860 P / 860 S

The V-Press 860 P vertical baler is specially designed for compacting opened or perforated PET bottles. The V-Press 860 S model is suitable for compacting hard plastics.

HSM V-Press 860 TimeSave

Thanks to a fast lift-tilt device, the press is filled with cardboard within a few seconds. Filling takes place by means of a collecting carriage in the rear part. The baling process starts automatically, strapping follows manually by means of quick-link wire. Compared to other automatically operating balers, the V-Press 860 vertical baler saves up to 1.5 hours per bale.

HSM V-Press 1160

With a maximum bale weight of 550 kg, the V-Press 1160 is the top model in the V-Press series with strong baling force and absolutely high efficiency.

We are happy to help you

Contact us for a consultation